Please Chooese

Feature

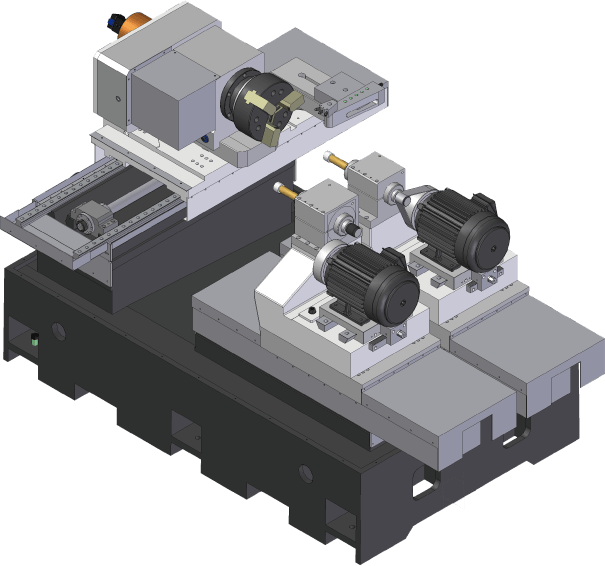

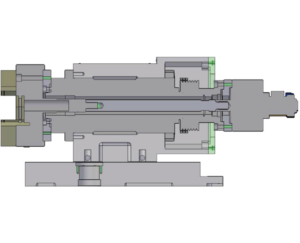

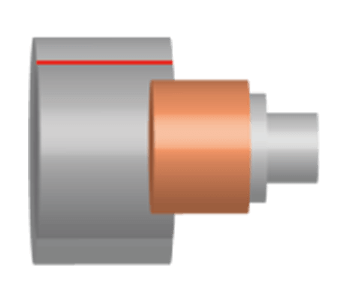

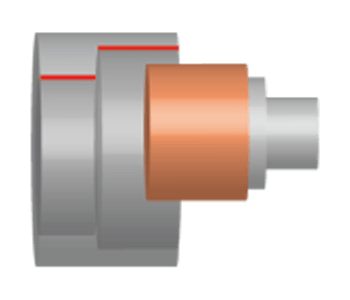

The spindle head design places the center of gravity at the rear portion to help balancing the whole spindle mechanism to increase spindle accuracy and loading capacity.

Spindle driven by servo motor offers optimum speed and torque performance.

Complete one piece cartridge spindle can avoid the eccentricity of spindle housing and reduces the heat increase for spindle longevity.

X axis lower slide design offers easy adjustment of the workhead for grinding parts with different lengths.

Machine incorporates roller type linear guide ways for X/Z/Y axes for high dynamic rigidity and better loading capacity. This drastically increases the grinding accuracy.

C1 grade precision ball screw with large leading pitch is used to achieve high accuracy.

Low-gravity base structure, with slant bed design for better coolant draining and grinding swarf removal.

Grinding Example

Standard grinding cycles and multi-steps graphic

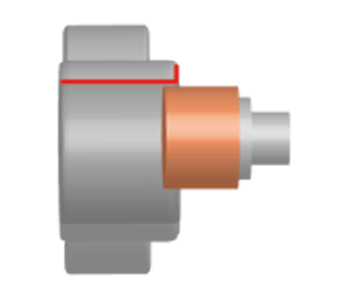

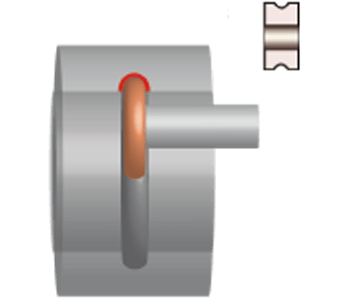

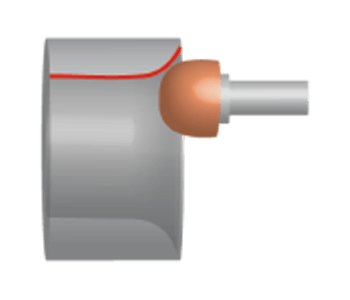

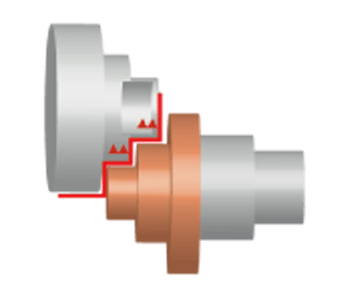

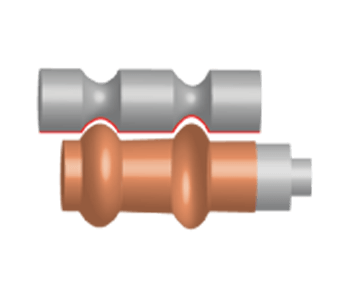

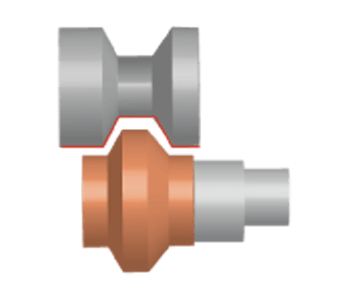

Inner through

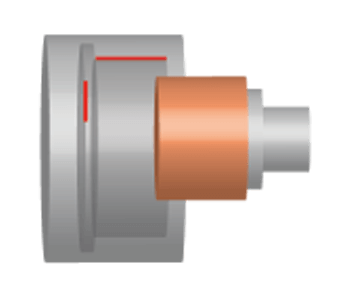

2 Step straight hole

Inner through hole + outer end-face

Inner blind hole + Inner end-face

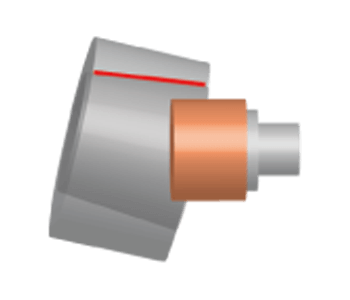

Inner taper

Inner blind hole + ID chamer

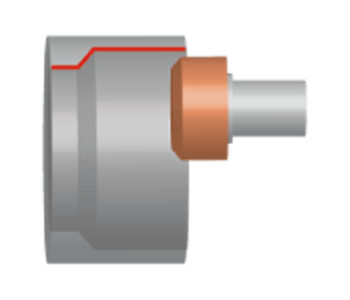

Inner radius groovin

Inner through hole + Inner radius

Multi-step grinding

Profile grinding

Form grinding

Specification

| Model | EGI-150 CNC |

|---|---|

| General capacity | |

| Max. grinding ID | φ11.8" |

| Max. grinding OD | φ11.8" |

| Swing over workhead | φ19.6" |

| Max. grinding depth | 10.2" |

| Max. weight of workpiece | 110 Lbs. |

| Max. length of workpiece | 11.8" |

| Type of workhead | A2-5 (A2-6 Opt.) |

| Workhead (X Axis) | |

| 3-Jaw chuck | Hydraculic - 8"/10"(opt.) |

| Swiveling angle range | +15°~ -5° |

| Manual travel distance (toward Z axis) | 9.8" |

| Spindle speed (infinite variable) | 0~1000 (Variable speed) rpm |

| Servo motor rated power | 1.8(F)/2.2(M) kw |

| Grinding weelhead(Y axis) | |

| OD grinding wheel size | N/A |

| ID grinding wheel size | N/A |

| Max. spindle speed | N/A |

| Spindle motor/ max. torque | N/A |

| Grinding Wheelhead (Z axis) | |

| OD grinding wheel size | N/A |

| ID grinding wheel size | φ3.9" |

| End-Surface grinding spindle (Opt.Z2) | φ3.1"(CBN) |

| Max. spindle speed | 20,000 (std.) rpm |

| Spindle motor/ max. torque | 3.75Kw / 13Nm |

| X axis | |

| Travel | 12.2" |

| Rapid feedrate | 314" In/min |

| Heidenhain linear scale resolution | 0.000002" |

| Min. increment | 0.000010" |

| Servo motor rated power | 1.8(F)/2.2(M) Kw |

| Y axis | |

| Travel | N/A |

| Rapid feedrate | N/A |

| Min. increment | N/A |

| Servo motor rated power | N/A |

| Z axis | |

| Travel | 13.7" |

| Rapid feedrate | 314" In/min |

| Min. increment | 0.000010" |

| Servo motor rated power | 1.8(F)/2.2(M) Kw |

| Motor | |

| Hydraulic motor | 0.75 Kw |

| Coolant pump | 0.37+0.18 Kw |

| Machine | |

| Net weight | 11203 Lbs. |

| Gross weight | 12125 Lbs. |

| Packing size (L x W x H) | 132"x88"x77" |

Accessories