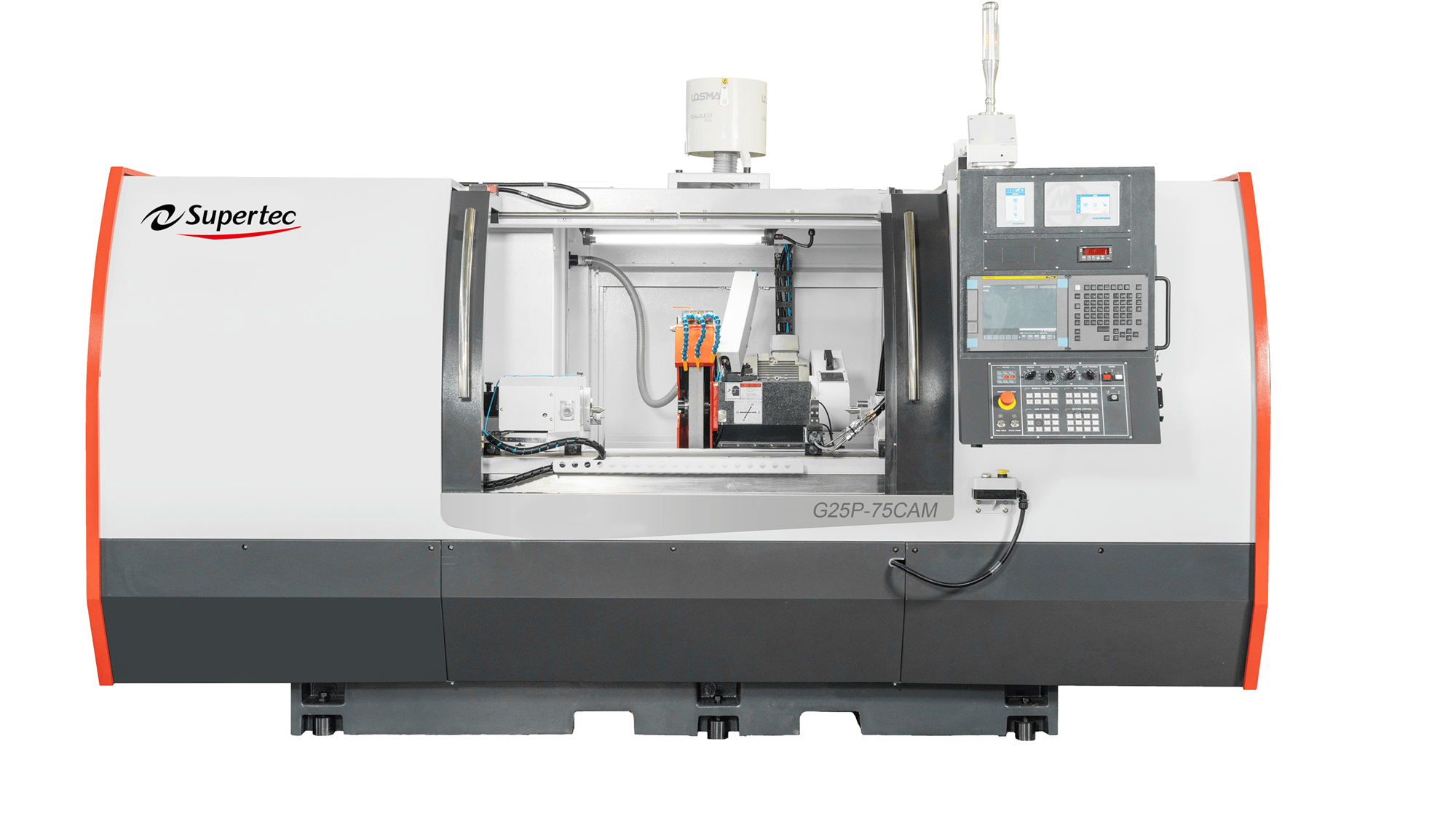

Supertec Enhances Its Industry-Leading Range of ID/OD Grinders

New Models Added to the EGM Series

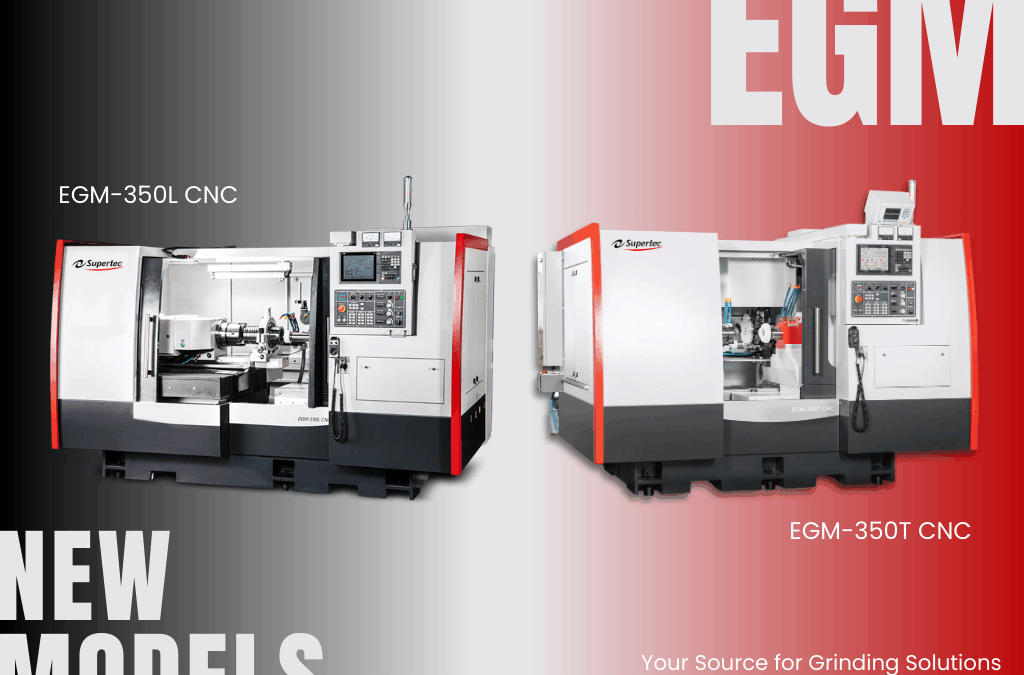

With the addition of the EGM-350L CNC and EGM-350T CNC, Supertec’s family of twin spindle ID/OD grinders has grown stronger. Coming with a single part clamping for both ID and OD, or rough and finish ID grinding, the EGM grinders are designed to improve cycle times and output (up to 40%) over single spindle models, allowing more fixability and offering a more specific customization for grinding applications.

Supertec’s EGM series of twin spindle ID/OD grinders are utilized in a variety of grinding applications, covering a broad range of industries including automotive, aerospace, medical instrument, machine tool, and tool and die. The EGM series grinders are versatile enough to be integrated into high production machining cells or small batch job shop applications.

EGM-80CNC is designed for shops with limited shop floor space. The twin ID spindles can be used to grind the ID, OD, shoulder, and face for small workpieces.

EGM-350CNC, the work horse of the EGM line, offers two ID spindles with a choice of RPM’s available. The EGM-350CNC grinder can grind the ID, OD, shoulder, and face of parts ranging from .23” ~ 15” diameter with a grind depth of 10”.

EGM-350L CNC is designed for long parts needing to be ID ground. With the use of a steady rest, the EGM-350L can hold parts up to 29” long with an ID grinding depth of 11.8”.

EGM-350T CNC offers an 8-position tool changer, allowing a broad range of grinding capabilities and options for both ID and OD applications. In a single set-up, the operator can rough and finish grind ID’s, OD’s and faces, drastically reducing the set-up and cycle time.

EGM-450CNC, this widely popular model offers an ID spindle with a 16” OD grinding wheel. The 16” OD increases the OD and Face grinding times significantly.

EGM-550L & XL CNC is a heavy-duty model for grinding parts up to 47” in length (EGM-550L) or 78” in length (EGM-550XL) and 600 lbs. weight capacity (with steady rest).