Please Chooese

Feature

Sturdy rigid-designed workhead is electronically controlled giving variable spindle speeds ranging from 30-350RPM.

Cartridge type wheel spindle is equipped with four super precision class 7 (ABEC) bearings.

One V and one flat hand-scraped guideways on the weelhead are Turcite coated and incorporated with an automatic lubrication system, precision ballscrew, and A.C. servomotor (NC version only) to ensure smooth movement of the wheelhead which delivers longer way life with superior positioning accuracy and repeatability.

Slideways, ballscrew is continuously lubericated by an auto-lube system to ensure long service life and maintain maximum accuracy.

Conversational PLC control uses a menu-driven LCD touch screen that is easy to set. Simply fill in the blanks to set total grinding amount, rough increment, fine increment, spark-out passes, feeding direction, parking position and retracting clearance. Press cycle start complete the automatic grind cycle. (NC models only)

Automatic trim compensation.

Grinding Applications

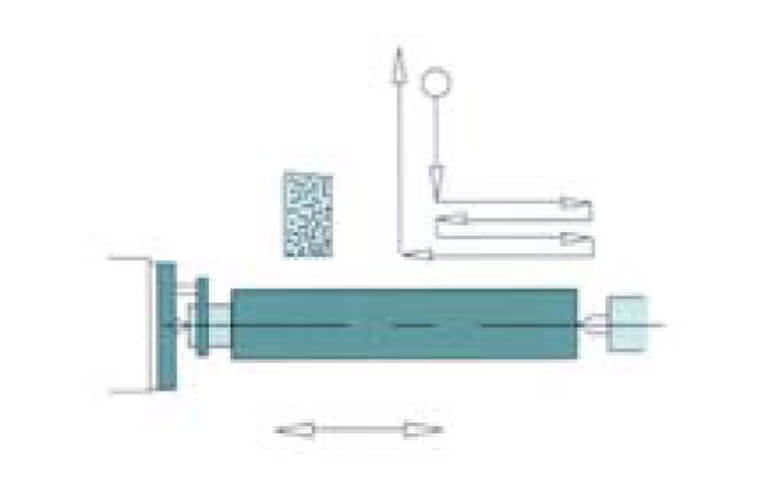

Traverse grinding with 2-centers Support

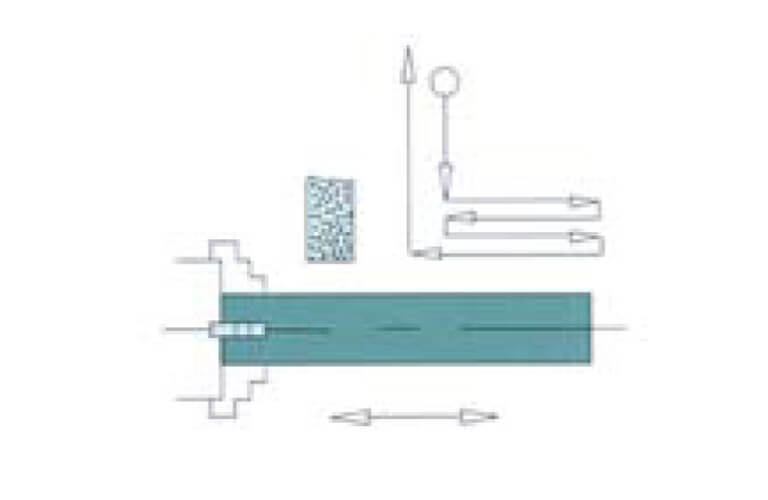

Traverse Grinding with chuck

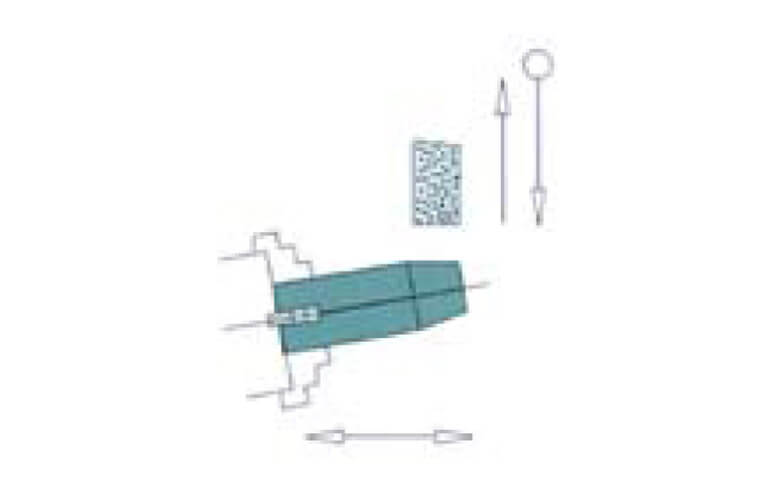

Taper Grinding with Chuck

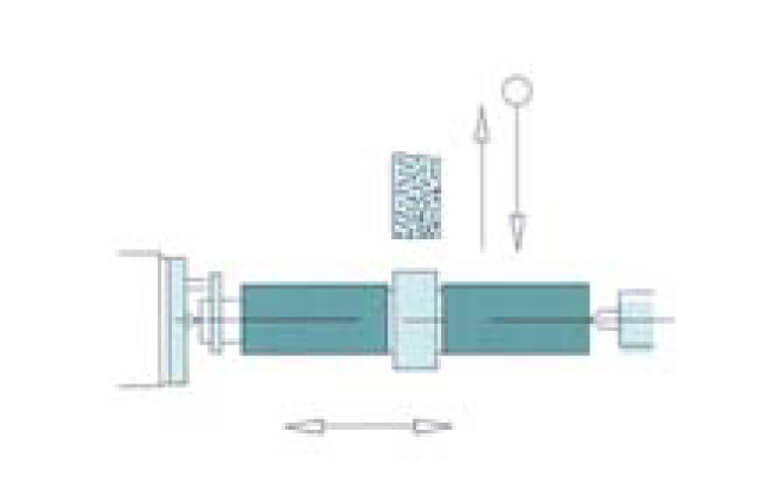

Plunge grinding

Traverse grinding with 2-centers Support

Surface Grinding

Specification

| Model | G25P-50NC | G32/G38P-60NC | G32/G38P-100NC | G32/G38P-150NC | G32/G38P-200NC |

|---|---|---|---|---|---|

| General Capacity | |||||

| Distance between Centers | 19.6″ | 23.6″ | 39.3″ | 59″ | 78.7″ |

| Swing over table | 10.2″ | 12.6″/15″ | 12.6″/15″ | 12.6″/15″ | 12.6″/15″ |

| Max. grinding diameter | 9.8″ | 11.8″/14″ | 11.8″/14″ | 11.8″/14″ | 11.8″/14″ |

| Max. Load held between centers | 176 lbs. | 330 Lbs. | 330 Lbs. | 330 Lbs. | 330 Lbs. |

| Wheelhead | |||||

| Swivelling angle (R & L) | ±30° | ±30° | ±30° | ±30° | ±30° |

| Infeed travel | 5.3″ | 9.6″ | 9.6″ | 9.6″ | 9.6″ |

| Hand feed travel | 3.5″ | 7.8″ | 7.8″ | 7.8″ | 7.8″ |

| Top slide travel | 7″ | 7″ | 7″ | 7″ | 7″ |

| Automatic rapid travel | 1-3/4″ | 1-3/4″ | 1-3/4″ | 1-3/4″ | 1-3/4″ |

| Auto increment infeed | 0.001″~0.1″ | 0.001″~0.1″ | 0.001″~0.1″ | 0.001″~0.1″ | 0.001″~0.1″ |

| Handwheel per graduation | 0.0002″ | 0.0002″ | 0.0002″ | 0.0002″ | 0.0002″ |

| Handwheel per revolution | 0.1″ | 0.1″ | 0.1″ | 0.1″ | 0.1″ |

| Grinding Wheel | |||||

| Diameter x Width x Bore | 14″x1.5″x5″ | 16″x2″x5″ | 16″x2″x5″ | 16″x2″x5″ | 16″x2″x5″ |

| Wheel Speed | 1,750 rpm | 1,650 rpm | 1,650 rpm | 1,650 rpm | 1,650 rpm |

| Table | |||||

| Swivelling Angle (R & L) Degree | ±8° | ±9° | ±7° | ±5° | ±3° |

| Traverse Speed (infinitely variable) | 1-1/5″~275″/ min | 1-1/5″~275″/ min | 1-1/5″~275″/ min | 1-1/5″~275″/ min | 1-1/5″~275″/ min |

| Handwheel per Revolution | 4″ | 4″ | 4″ | 4″ | 4″ |

| Workhead | |||||

| Swivelling Angle (R & L) degree | ±45° | 90° | 90° | 90° | 90° |

| Center Taper | MT3 | MT4 (opt. MT5, 5C) | MT4 (opt. MT5, 5C) | MT4 (opt. MT5, 5C) | MT4 (opt. MT5, 5C) |

| Spindle Speed (infinitely variable) | 150/264/356/480 rpm | 30~350 rpm | 30~350 rpm | 30~350 rpm | 30~350 rpm |

| Tailstock | |||||

| Center Taper | MT3 | MT4 (opt. MT5) | MT4 (opt. MT5) | MT4 (opt. MT5) | MT4 (opt. MT5) |

| Quill Travel | 1″ | 1″ | 1″ | – | – |

| Internal Grinding | |||||

| Available Spindle Speed | 20,000 rpm | 20,000 rpm | 20,000 rpm | 20,000 rpm | 20,000 rpm |

| Max. Grinding Bore | 1.18″- 3.94″ or 0.79″-1.97″ | 1.18″- 3.94″ or 0.79″-1.97″ | 1.18″- 3.94″ or 0.79″-1.97″ | 1.18″- 3.94″ or 0.79″-1.97″ | 1.18″- 3.94″ or 0.79″-1.97″ |

| Max. Grindind Length | 4.33″ or 2.17″ | 4.33″ or 2.17″ | 4.33″ or 2.17″ | 4.33″ or 2.17″ | 4.33″ or 2.17″ |

| Max. Chucking Length | 12-2/5″ | 12-2/5″ | 12-2/5″ | 12-2/5″ | 12-2/5″ |

| Max. Chucking Diameter | 6″ | 6″ | 6″ | 6″ | 6″ |

| Motor | |||||

| Wheel spindle Motor | 5 HP | 7 1/2 HP | 7 1/2 HP | 7 1/2 HP | 7 1/2 HP |

| Workhead Motor | 1/2 HP | 2 HP | 2 HP | 2 HP | 2 HP |

| Hydraulic Pump | 2 HP | 2 HP | 2 HP | 2 HP | 2 HP |

| Coolant Pump | 1/8 HP | 1/4 HP | 1/4 HP | 1/4 HP | 1/4 HP |

| Internal Grinding Motor | 2 HP | 2 HP | 2 HP | 2 HP | 2 HP |

| Machine | |||||

| Net Weight (approx.) | 4,510 Lbs. | 8,580 Lbs. | 10,340 Lbs. | 11,660 Lbs. | 12,540 Lbs. |

| Gross Weight (approx.) | 5,610 Lbs. | 9,460 Lbs. | 11,440 Lbs. | 12,760 Lbs. | 14,520 Lbs. |

| Packing Dimension (L x W x H) | 89″x65″x75″ | 119″x90″x79″ | 119″x90″x79″ | 170″x90″x79″ | 203″x90″79″ |

Accessories