Please Chooese

Feature

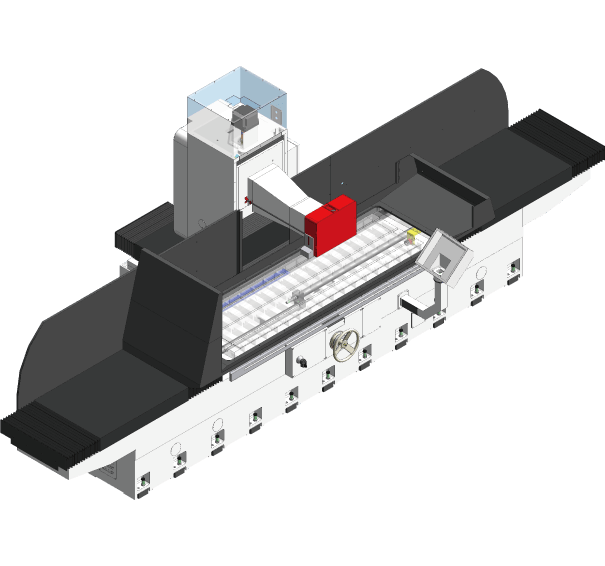

Machine design

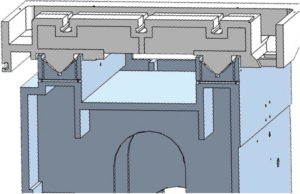

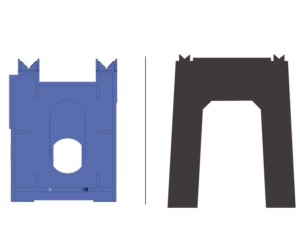

435mm(17.12“)wide column design: Comparing with other manufacturer, it provides better stability and rigidity.

Wheel spindle air blowing design

Wheel spindle air blowing design could create positive pressure. It effectively prevents dust going into the spindle, and maintains the internal coolant of the spindle. The catrige spindle itself has a outer spiral groove design, and it could effectively prevents the spindle from thermal raising.

15HP spindle motor

Heavy duty spindle with 15HP spindle motor allows the machine to grind hard material or to grind with creep feeding operation

Machine design

774mm wide machine base design provides excellent machine rigidity, and low dynamic grinding operation

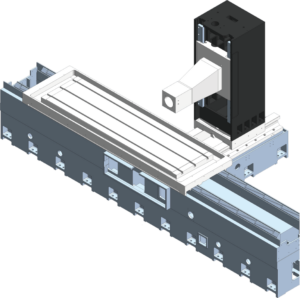

X Axis Working table guideway double V design

X Asis guideway is precisely hand scraped, oil firm lubrication supplied, and Turcite-B coated to ensure positioning accuracy and long term usage.

Rigid rib-box structure

Rigid rib-box structure is consist with the same material level of Meehanite base casting, ensuring the machine rigidity and stability.Machine net weight: 2,200kg.

Grinding Example

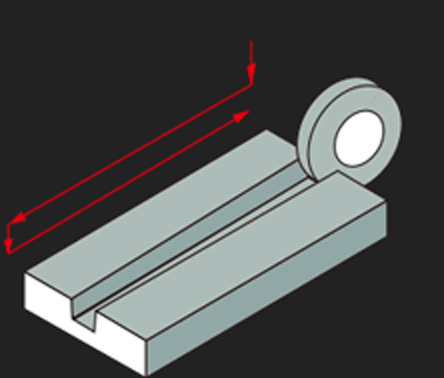

Cll Grinding mode

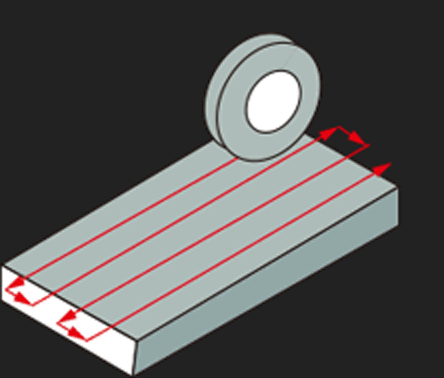

Step cross

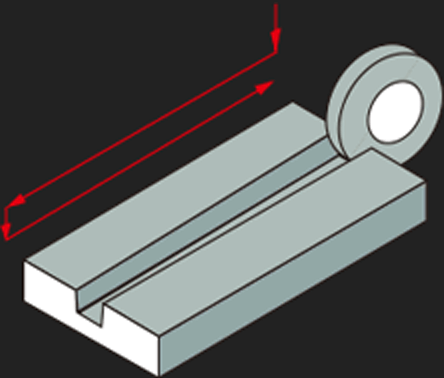

Plunge

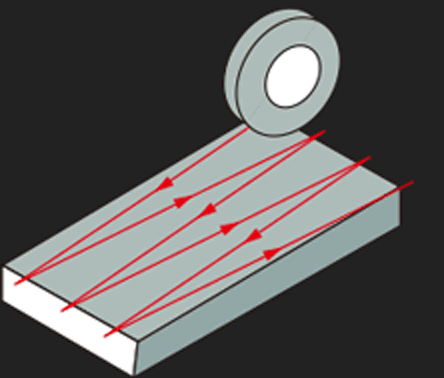

Crisscross

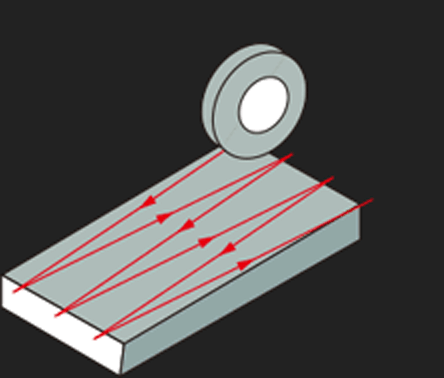

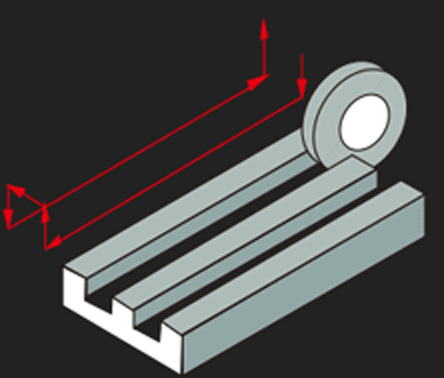

CXll Grinding mode

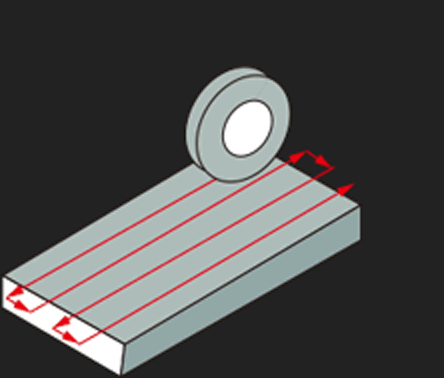

Step cross

Plunge

Crisscross

Slice

Specification

| Model | 820NC | 1224NC | 1632NC | 2040NC | 2060NC | 2448NC | 2460NC | 2480NC | 24100NC | 24120NC |

|---|---|---|---|---|---|---|---|---|---|---|

| Table Size | 8″x20″ | 12″x24″ | 16″x32″ | 20″x47″ | 20″x59″ | 24″x47″ | 24″x59″ | 24″x78″ | 24″x98″ | 24″x117″ |

| Max. Grinding Length | ||||||||||

| Longitudinal | 20″ | 24″ | 34″ | 49″ | 61″ | 49″ | 61″ | 80″ | 100″ | 119″ |

| Max. Grinding Width | ||||||||||

| Crosswise | 8″ | 12″ | 16″ | 20″ | 20″ | 24″ | 24″ | 24″ | 24″ | 24″ |

| Standard Chuck Size | 8″x20″ | 12″x24″ | 16″x32″ | 20″x40″ | 20″x59″ | 24″x47″ | 24″x59″ | 24″x78″ | 24″x98″ | 24″x117″ |

| Max. Distance from Table Surface to Spindle Centerline | 20″ | 22″ | 22″ | 24″ | 24″ | 28″ | 28″ | 28″ | 28″ | 28″ |

| Table Longitudinal Tracel (X axis) | ||||||||||

| Hydraulic Traverse | 22″ | 26″ | 34″ | 44″ | 63″ | 49″ | 61″ | 80″ | 100″ | 119″ |

| Max. Traverse (Manual) | 24″ | 28″ | 36″ | 46″ | 65″ | 51″ | 63″ | 82″ | 102″ | 121″ |

| Table Speed, Infinitely Variable | 1~82 fpm | 10~82 fpm | 10~82 fpm | 10~82 fpm | 10~82 fpm | 10~105 fpm | 10~105 fpm | 10~105 fpm | 10~105 fpm | 10~105 fpm |

| Cross Travel (Z axis) | ||||||||||

| Rapid Travel, approx | 2~3 fpm | 2~3 fpm | 2~3 fpm | 2~3 fpm | 2~3 fpm | 0.9~5 fpm | 0.9~5 fpm | 0.9~5 fpm | 0.9~5 fpm | 0.9~5 fpm |

| Automatic Traverse Increment | 0.02″~0.4″ | 0.02″~0.4″ | 0.02″~0.4″ | 0.02″~0.4″ | 0.02″~0.4″ | 0.02″~0.4″(Opt. 0.004″~1.57″) | 0.02″~0.4″(Opt. 0.004″~1.57″) | 0.02″~0.4″(Opt. 0.004″~1.57″) | 0.02″~0.4″(Opt. 0.004″~1.57″) | 0.02″~0.4″(Opt. 0.004″~1.57″) |

| Cross Traverse (Automatic) | 8.5″ | 14.5″ | 18.5″ | 22″ | 22″ | 25.5″ | 25.5″ | 25.5″ | 25.5″ | 25.5″ |

| Max. Traverse (Manual) | 9″ | 15″ | 19″ | 25″ | 25″ | 26″ | 26″ | 26″ | 26″ | 26″ |

| Handwheel per Revolution | 0.2″ | 0.2″ | 0.2″ | 0.2″ | 0.2″ | MPG 0.01″/0.1″/0.5″ | MPG 0.01″/0.1″/0.5″ | MPG 0.01″/0.1″/0.5″ | MPG 0.01″/0.1″/0.5″ | MPG 0.01″/0.1″/0.5″ |

| Handwheel per Graduation | 0.0125″ | 0.0008″ | 0.0008″ | 0.0008″ | 0.0008″ | MPG 0.0001″/0.001″/0.005″ | MPG 0.0001″/0.001″/0.005″ | MPG 0.0001″/0.001″/0.005″ | MPG 0.0001″/0.001″/0.005″ | MPG 0.0001″/0.001″/0.005″ |

| Wheelhead Vertical Infeed | ||||||||||

| Automatic Infeed | 0.00005″~0.004″ | 0.00004″~0.002″ | 0.00004″~0.002″ | 0.00004″~0.002″ | 0.00004″~0.002″ | 0.00004″~0.001″ | 0.00004″~0.001″ | 0.00004″~0.001″ | 0.00004″~0.001″ | 0.00004″~0.001″ |

| Handwheel per Revolution (MPG) | 0.004″ | 0.004″/0.04″/0.4″ | 0.004″/0.04″/0.4″ | 0.004″/0.04″/0.4″ | 0.004″/0.04″/0.4″ | 0.01″/0.05″/0.1″ | 0.01″/0.05″/0.1″ | 0.01″/0.05″/0.1″ | 0.01″/0.05″/0.1″ | 0.01″/0.05″/0.1″ |

| Handwheel per Graduation (MPG) | 0.00004″ | 0.00004″/0.004″/0.04″ | 0.00004″/0.004″/0.04″ | 0.00004″/0.004″/0.04″ | 0.00004″/0.004″/0.04″ | 0.0001″/0.0005″/0.001″ | 0.0001″/0.0005″/0.001″ | 0.0001″/0.0005″/0.001″ | 0.0001″/0.0005″/0.001″ | 0.0001″/0.0005″/0.001″ |

| Grinding Spindle | ||||||||||

| Speed | 3600rpm | 1780rpm | 1780rpm | 1780rpm | 1780rpm | 1800rpm | 1800rpm | 1800rpm | 1800rpm | 1800rpm |

| Motor | 3HP/5HP(Opt.) | 7.5HP/10HP(Opt.) | 7.5HP/10HP(Opt.) | 10HP/15HP(Opt.) | 10HP/15HP(Opt.) | 15HP/20HP(Opt.) | 15HP/20HP(Opt.) | 15HP/20HP(Opt.) | 15HP/20HP(Opt.) | 15HP/20HP(Opt.) |

| Grinding Wheel | ||||||||||

| Diameter x Width x Bore | ø8″x0.5″xø1.25″ | ø14″x2″xø5″ | ø14″x2″xø5″ | ø14″x2″xø5″ | ø14″x2″xø5″ | ø20″x2″xø5″ | ø20″x2″xø5″ | ø20″x2″xø5″ | ø20″x2″xø5″ | ø20″x2″xø5″ |

| Crossfeed Motor | 40W | 0.2KW | 0.2KW | 1/4HP | 1/4HP | 1KW(Servo) | 1KW(Servo) | 1KW(Servo) | 1KW(Servo) | 1KW(Servo) |

| Elevating Motor | 40W | 1KW | 1KW | 1KW | 1KW | 3KW(Servo) | 3KW(Servo) | 3KW(Servo) | 3KW(Servo) | 3KW(Servo) |

| Hydraulic Motor | 1HP | 2HP | 2HP | 5HP | 5HP | 5HP | 5HP | 5HP | 5HP | 5HP |

| Weight | ||||||||||

| Net Weight, approx. | 3240LB | 6614LB | 8598LB | 10560LB | 15653LB | 11905LB | 19400LB | 15565LB | 17434LB | 19467LB |

| Gross Weight, approx | 3571LB | 7055LB | 9259LB | 11880LB | 18960LB | 17813LB | 21605LB | 22046LB | 24030LB | 26433LB |

| Packing Size | ||||||||||

| Length x Width x Height | 87″x63″x87″ | 113″x89″x99″ | 121″x89″x101″ | 131″x90″x100″ | 177″x89″x100″ | 138″x90″x96″ | 204″x90″x101″ | 178″x91″x99″ | 300″x111″x103″ | 300″x111″x103″ |

Accessories