Please Chooese

Feature

Sand Repairing Device

A hydraulic dressing unit on both the grinding and regulating wheels with precisely handscraped guide ways provides stable hydraulic movement and the best dressing effects. Various types of form dressing can be achieved with optional templates.

- NC model: optional auto. grinding wheel dressing device enables count dressing, time dressing, or auto dressing and compensation

- CNC model: with two axes servo control and the automatic compensation system can precisely dress forms with complicated shapes.

- Various workrest design: E-tech developed various kinds of workrest based on different diameter of workpieces, which are easy for operating adjustment.

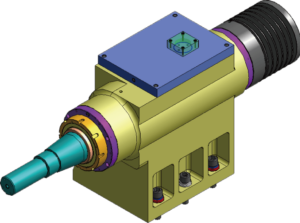

Spindle: Dynamic/Static Pressure Spindle

Both grinding & regulating wheel spindles are made of Ni-Cr-Mo alloy steel, which is normalized, carbonized, hardened and grounded.

Adjustment Wheel Servo Vontrol

The regulating wheel utilizes a servo motor which provides infinitely variable speeds. The speed can be set digitally to reach constant surface speeds even when the diameter of the regulating wheel changes. Consequently, better surface finishes and roundness of the workpiece can be achieved. A beltdriven transmission system is also adopted for the regulating wheel for less vibration and noise compare to traditional chain-driven system

Stop Grinding Automatic Feed (NC Type)

Automatic infeed models (NC) are equipped with a PLC touch screen control with easy learning conversational software.

An infeed grinding cycle can be completed by simply choosing the grinding cycle mode (single or automatic), inputting grinding data and then pressing cycle start.

A double inverted “V” slideway with optimum spacing for the regulating wheel assembly provides smooth movement and stable grinding operation.

The machine base is made of Meehanite castings designed to reduce vibration. The machine base provides stable support to the grinding wheel and regulating wheel assemblies to ensure a rigid machine foundation and better accuracy.

Grinding Example

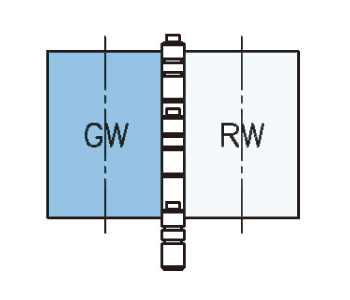

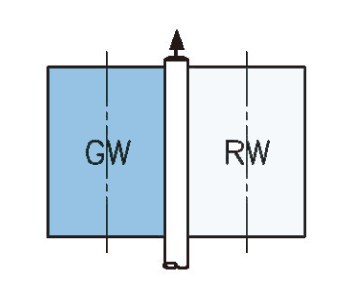

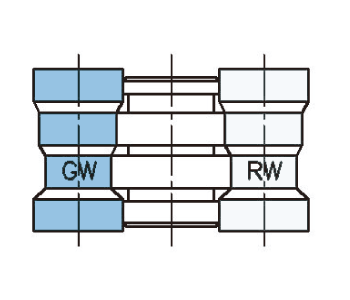

Cll Grinding mode

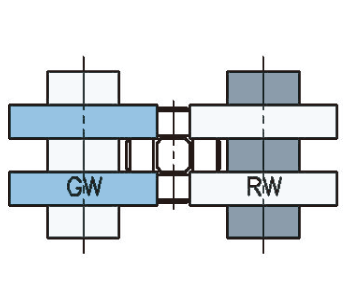

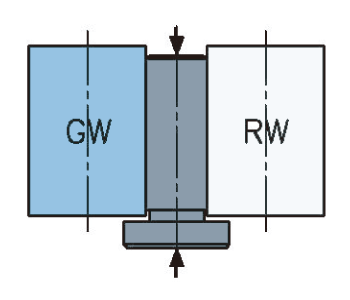

Thrufeed grinding

Thrufeed grinding

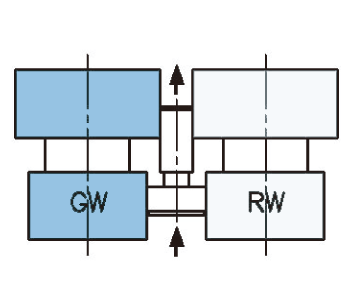

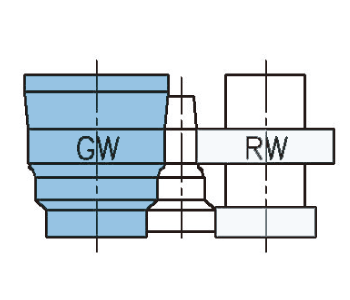

Infeed grinding

Infeed grinding

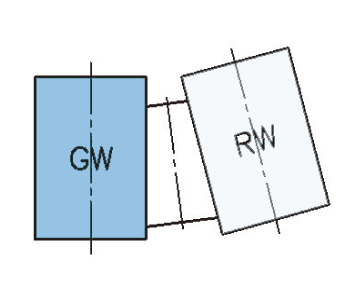

Infeed grinding

Infeed grinding

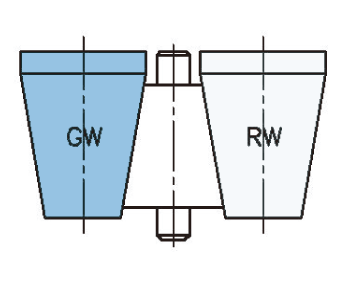

Infeed grinding

Infeed grinding

Infeed grinding

Specification

| Model | Unit | STC-CNC 1808/1810/1812 |

STC-CNC 2008/2010/2012 |

STC-CNC 2408/2410/2412 |

|---|---|---|---|---|

| Grinding Capacity | ||||

| Work diameter (w/standard workrest) | Ø0.04″~2.36″ | Ø0.04″~2.36″ | Ø0.04″~3.14″ | |

| Work diameter (w/special workrest) | Ø2.36″~4″ | Ø2.36″~4.7″ | Ø3.14″~5.9″ | |

| Auto infeed min. increment | 0.000010″ | 0.000010″ | 0.0000010″ | |

| Grinding Wheel | ||||

| Wheel size (OD x Width x ID) 08type | φ18″x8″xφ9″ | φ20″x8″xφ12″ | φ24″x8″xφ12″ | |

| Wheel size (OD x Width x ID) 10type | φ18″x10″xφ9″ | φ20″x10″xφ12″ | φ24″x10″xφ12″ | |

| Wheel size (OD x Width x ID) 12type | φ18″x12″xφ9″ | φ20″x12″xφ12″ | φ24″x12″xφ12″ | |

| Motor rated power / max. torque | HP/Nm | 15/17(Opt.20/97) | 20/97(Opt.25/120) | 20/97(Opt.30/143) |

| Spindle speed | rpm | 1400 | 1250 | 1050 |

| Dressing infeed servo motor (X, opt) | HP/Nm | 0.54 / 2.5 | 0.54 / 2.5 | 0.54 / 2.5 |

| Dressing traverse servo motor (Y, opt) | HP/Nm | 1 / 4.9 | 1 / 4.9 | 1 / 4.9 |

| Regulating Wheel | ||||

| Wheel size (OD x Width x ID) 08 type | φ10″x8″xφ4.3″ | φ12″x8″xφ5″ | φ14″x8″xφ6″ | |

| Wheel size (OD x Width x ID) 10 type | φ10″x10″xφ4.3″ | φ12″x10″xφ5″ | φ14″x10″xφ6″ | |

| Wheel size (OD x Width x ID) 12 type | φ10″x12″xφ4.3″ | φ12″x12″xφ5″ | φ14″x12″xφ6″ | |

| Regulating wheel motor | HP | 4 | 4 | 6.7 |

| Spindle speed (infinite variable) | rpm | 15-310 | 15-310 | 15-310 |

| Dressing infeed servo motor (X1, opt) | HP | 0.54 | 0.54 | 0.54 |

| Dressing traverse servo motor (Y1, opt) | HP | 1 | 1 | 1 |

| Lower slide infeed servo motor (Z, opt) | HP | 2.4 | 2.4 | 3.35 |

| Regulating wheel infeed servo motor (Z1, opt) | HP | 1.6 | 1.6 | 1.6 |

| Swivelling angle (L/R) | deg | ±5° | ±5° | ±5° |

| Min. infeed unit | 0.000010″ | 0.000010″ | 0.000010″ | |

| Inclining angle (F/R) | deg | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° |

| Motor | ||||

| Hydraulic motor | HP | 1 | 1 | 1 |

| Machine | ||||

| Net Weight (semi-enclosed splash guard) | Lbs. | 7,275 | 7,495 | 13,448 |

| Gross weight | Lbs. | 7,936 | 8,157 | 14,550 |

| Packing size (L x W x H) | 106″x88″x73″ | 106″x88″x73″ | 141″x88″x81″ | |

Accessories