Please Chooese

Feature

B-axis rotary table

Plunge type OD wheel

Anglehead OD wheel

ID spindle

Specification

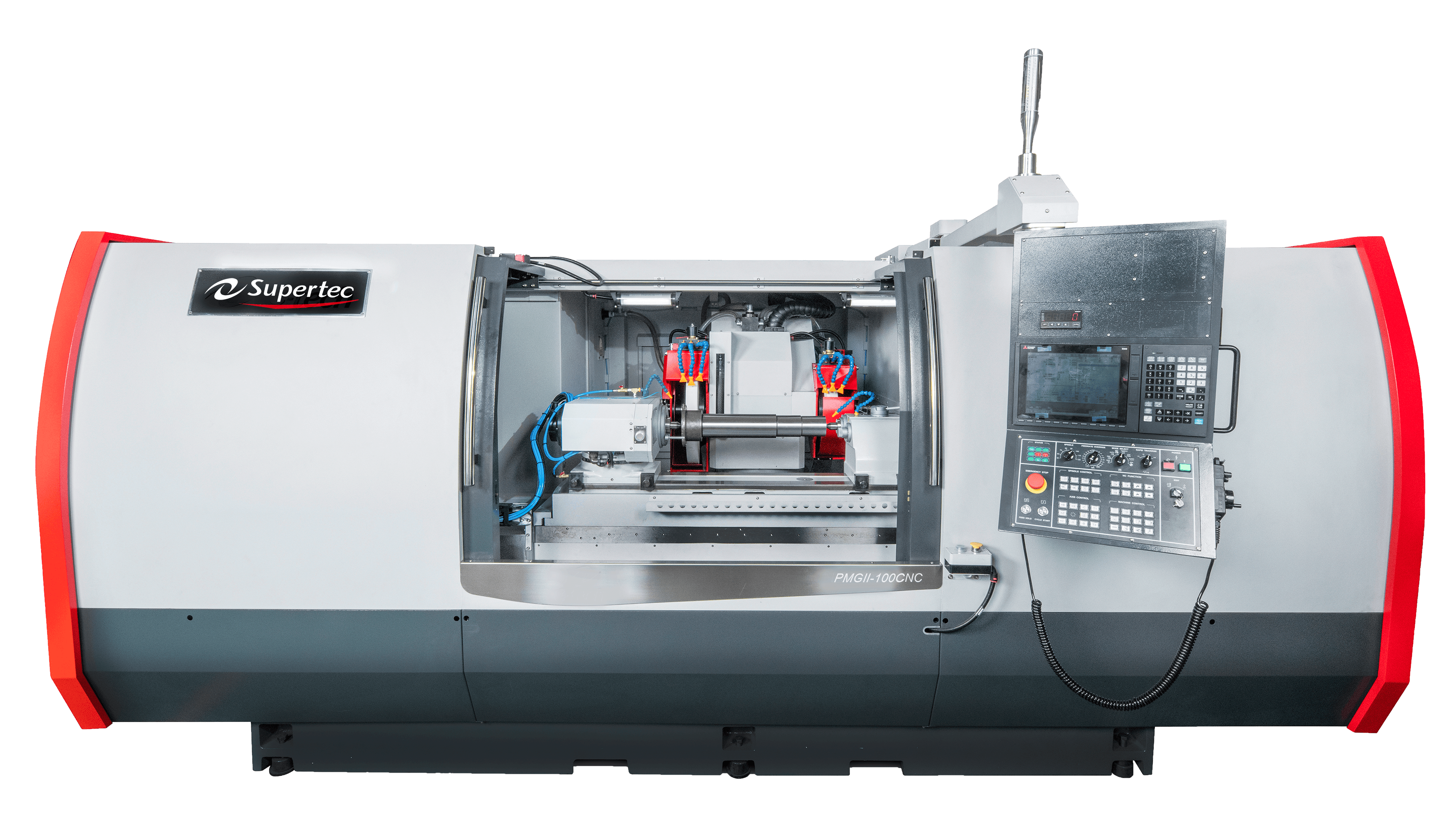

| Model | PMGII-60CNC | PMGII-100CNC | PMGII-150CNC |

|---|---|---|---|

| Ginding Capacity | |||

| Swing Over Table | ø15″ | ø15″ | ø15″ |

| Distance Between Centers | 23.6″ | 39.4″ | 59″ |

| Max. Grinding Diameter | 14.1″ | 14.1″ | 14.1″ |

| Max. Weight Between Centers | 330 lbs | 330 lbs | 330 lbs |

| Center Distance Between Spindle & Slide Table | 7.5″ | 7.5″ | 7.5″ |

| Grinding Wheel | |||

| Wheel Size-LH (DxWxB) | 20″x2″x6″ | 20″x2″x6″ | 20″x2″x6″ |

| Wheel Size-RH (DxWxB) | 16″x2″x6″ | 16″x2″x6″ | 16″x2″x6″ |

| Motor Rated Power/Max. Torque | 10 hp/ 49 nm | 10 hp/ 49 nm | 10 hp/ 49 nm |

| Wheel Speed | 1250 rpm (Opt.1650 rpm) | 1250 rpm (Opt.1650 rpm) | 1250 rpm (Opt.1650 rpm) |

| Workhead | |||

| Swiveling Angle | 90° | 90° | 90° |

| Spindle Speed (infinite variable) | 10~600 rpm | 10~600 rpm | 10~600 rpm |

| Motor Rated Power | 1.5 kw | 1.5 kw | 1.5 kw |

| Center Taper | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) |

| Spindle Type | Fixed or Rotary | Fixed or Rotary | Fixed or Rotary |

| Diameter of Bore | 1.023″ | 1.023″ | 1.023″ |

| Tailstock | |||

| Quill Travel | 1″ (Opt. 2″) / 3″ | 1″ (Opt. 2″) / 3″ | 1″ (Opt. 2″) / 3″ |

| Center Taper | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) |

| X Axis | |||

| Travel | 11″ | 11″ | 11″ |

| Max. Rapid Feed Rate | 236″ / min | 236″ / min | 236″ / min |

| Linear Scale Resolution | 0.000002″ | 0.000002″ | 0.000002″ |

| Min. Increment | 0.000004″ | 0.000004″ | 0.000004″ |

| Servo Motor Rated Power | 1.8kw (F) / 2.2kw (M) | 1.8kw (F) / 2.2kw (M) | 1.8kw (F) / 2.2kw (M) |

| Z Axis | |||

| Travel | 43.3″ | 57″ | 80.7″ |

| Max. Rapid Feed Rate | 315″ / min | 315″ / min | 315″ / min |

| Swiveling Angle | ±9° | ±7° | ±5° |

| Min. Increment | 0.000004″ | 0.000004″ | 0.000004″ |

| Servo Motor Rated Power | 1.8kw (F) / 2.2kw (M) | 1.8kw (F) / 2.2kw (M) | 2.2kw (F) / 3.5kw (M) |

| B Axis | |||

| Swiveling Angle | -30°~+210° | -30°~+210° | -30°~+210° |

| Max. Rotation Speed | 15 rpm | 15 rpm | 15 rpm |

| Min. Increment | 1° | 1° | 1° |

| Servo Motor Rated Power | 1.2kw (F) / 1.5kw (M) | 1.2kw (F) / 1.5kw (M) | 1.2kw (F) / 1.5kw (M) |

| Motor | |||

| Hydraulic Pump | ½ hp | ½ hp | ½ hp |

| Guide Way Lubrication Pump | ¼ hp | ¼ hp | ¼ hp |

| Coolant Pump | ¼ hp | ¼ hp | ¼ hp |

| Machine | |||

| Net Weight (semi-enclosed splash guard) | 12,760 lbs | 13,420 lbs | 14,300 lbs |

| Gross Weight | 14,520 lbs | 15,180 lbs | 16,060 lbs |

Accessories

Standard Accessories

Mitsubishi M80 control w/ iGrind conversational programming software

T1 plunge wheel (Ø20”x2”xØ6”)

T2 angular wheel (Ø16”x2”xØ6”)

T3 ID std. wheel(w/ ID spindle 20,000 rpm)+wheel arbor

Automatic 8 step wheel speed change w/ Yaskawa Inverter(10HP)

Infinite variable workhead w/ Yaskawa servo motor

Grinding wheel extractor

X-Axis linear scale (Renishaw)

B axis rotary index table -30~+210° (Min. increment 1°)

MT4 workhead spindle (opt. MT5)

2 pcs 6” wheel flanges

Diamond Dresser and Standard (work head ) T1 T2/ID T3 total 2 set)

Tools & Tool Box

4 color signal light

Carbide center tip MT4 C14 x2pc

LED Working Light

Operation manual & part lists

Electricity cabinet w/ heat exchanger

Roller type balancing stand/ arbor

Coolant system magnetic separator and paper filter (120L)

Guideway lubrication oil cooler

Hydraulic tailstock (w/ foot pedal)

Full enclosure splash guard w/oil & mist separator

Optional Accessories

Automatic 3-jaw hydraulic chuck w/ back plate (8”)

Manual 3-jaw hydraulic chuck w/ backplate (7”)

Built-in type ID spindle 40,000 ~ 60,000 rpm w/ dressing seat

Workpiece supporting seat (2 pcs)

2-point steady rest (Ø20~70mm)

2-point steady rest (Ø70~120mm)

3-point steady rest (Ø70~120mm)

3-point steady rest (Ø120~200mm)

*MT5 taper on workhead & tailstock

Grinding Wheel plunge type (20”x2.5”x6”)

Grinding Wheel angular type (16”x2.5”x6”)

6” wheel flange

Touch probe T18

*Gap control

Auto sizing

Transformer (15KVA)